Components Heat Treatment

strength and safety Heat Treatment.

Heat treating glass—through a controlled tempering process—significantly improves its durability and performance. Compared to annealed glass, heat-treated glass offers greater resistance to thermal and mechanical stresses and is engineered to break in specific patterns that enhance safety in glazing applications. This transformation occurs as the glass passes through a tempering furnace, altering its physical characteristics to meet demanding structural and environmental requirements. At Viracon, heat treatment is performed prior to applying Low-E coatings in accordance with ASTM C1048 standards for heat-strengthened and fully-tempered flat glass.

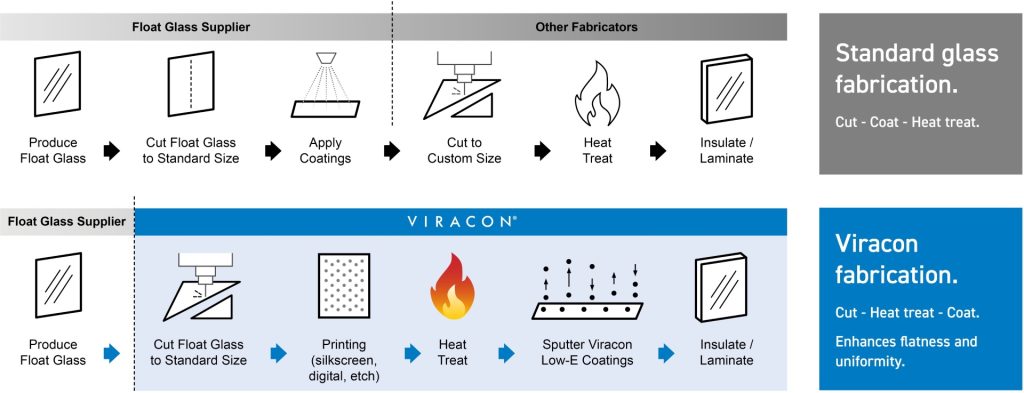

fabrication Process.

Precise control of temperature, timing and conveyor movements is vital for producing glass that has exceptional visual uniformity. Our unique fabrication process helps us achieve a higher standard for glass flatness. Cutting and heat treating prior to applying Low-E coatings delivers a flatter, more uniform glass outcome.

Visual Distortion Quality.

By heat treating before coating, we reduce visual distortion and deliver flatter, higher-quality glass. Measured in millidiopters, our enhanced internal flatness specification provides a more precise, complete, and reliable standard—ensuring architects and building owners get glass with superior aesthetics and performance.

View the Flatness Specification section below for more details.

TreatmentOptions.

There are two kinds of heat-treated glass, heat-strengthened (HS) and fully tempered (FT).

Annealed (AN)

No heat treatment

Raw float glass

Skips the heat-treating process during fabrication

Breaks into large shards

Heat-Strengthened (HS)

2x stronger than annealed

- 2x stronger than annealed glass of the same thickness, size, and type

- Surface compression for thicknesses ≤ 1/4” (6mm) = 4,000 – 7,000 psi

- Surface compression for thicknesses 5/16” (8mm) and 3/8” (10mm) = 5,000 – 8,000 psi

- Due to reader repeatability and instrument tolerances, Viracon’s tolerance for heat-strengthened glass surface compression is +/- 1,000 psi.

- Breaks into large shards

- While improving the strength and resistance to thermal shock and stress, heat-strengthened glass does not meet safety glazing requirements as outlined by the American National Standards Institute (ANSI) Z97.1 or the federal safety standard Consumer Products Safety Commission (CPSC) 16 CFR 1201 and therefore should not be used in these applications.

Fully Tempered (FT)

4x stronger than annealed

- 4x stronger than annealed glass and 2x stronger than heat-strengthened glass of same thickness, size, and type

- Minimum surface compression is 10,000 psi

- Potential for nickel sulfide inclusions (NiS). See Heat Soaking

- Breaks into fairly small pieces, reducing the chance for injury

- Qualifies as safety glass as outlined by the American National Standards Institute (ANSI) Z97.1 or the federal safety standard Consumer Product Safety Commission (CPSC) 16 CFR 1201

Heat Soaking

Minimize potential for spontaneous breakage

Fully tempered glass may break without warning due to the expansion of nickel sulfide inclusions (NiS) present within float glass. Because of the higher surface compression of fully tempered glass (10,000 psi), there is a potential for these nickel sulfide inclusions to expand and cause spontaneous breakage.

- Heat soak testing helps to minimize the potential for spontaneous breakage.

- Fully-tempered glass is placed into a heat soak oven and subjected to temperatures ranging from 290 to 550 degrees F for a two-hour dwell time, in accordance with EN 14179-1.

- Viracon heat soaks 100% of its heat-treated glass

- For more information, refer to our Heat Soak Testing Tech Talk

Flatness Specification

Optical distortion measured in millidiopters

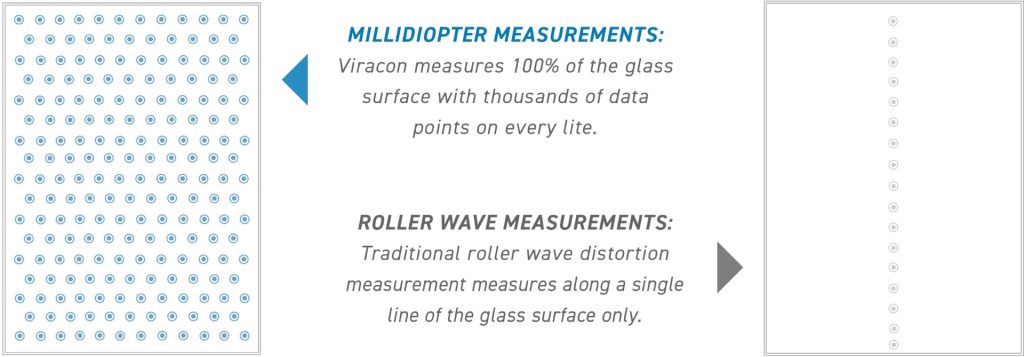

Measurement Technology

Old Way: Traditional, manual tools for measuring and quality control - roller wave trolley and zebra boards. These limited methods are two-dimensional, subjective, outdated and do not measure the full surface of the glass.

New Way: A precise, comprehensive approach using advanced digital distortion measurement systems that instantly scan 100% of the glass surface for optical distortion and report results in millidiopters (mD).

Measuring in Millidiopters

A millidiopter (mD) is a unit of measurement that quantifies the curvature of glass surfaces and represents optical distortion that our eyes can see.

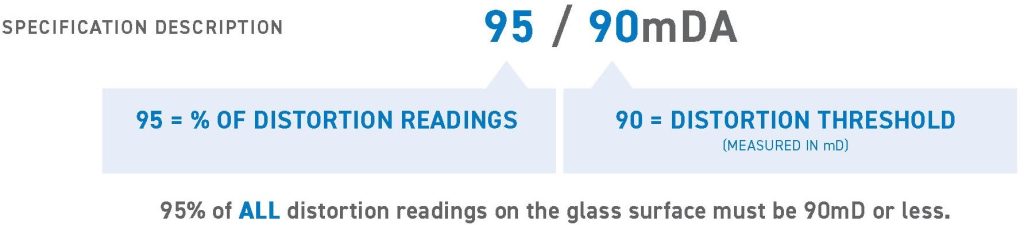

Specification Description

Internal Flatness Specification

| Thickness | mDA (All surface area) | mDL (Leading edge) | mDT (Trailing edge) |

|---|---|---|---|

| 6mm (1/4") | 95/100 | 95/175 | 95/175 |

| 8mm (5/16") to 12mm (1/2") | 95/90 | 95/135 | 95/135 |

Specification includes 3 points of measurement

mDA = Measurement across ALL surface area of the glass lite

mDL = Measurement in the LEADING edge area of the lite

mDT = Measurement in the TRAILING edge area of the lite

- Includes all substrate tints

- Excludes: pre-coated substrates (RoomSide Low-E), ceramic enamel, silkscreen or digital ink.