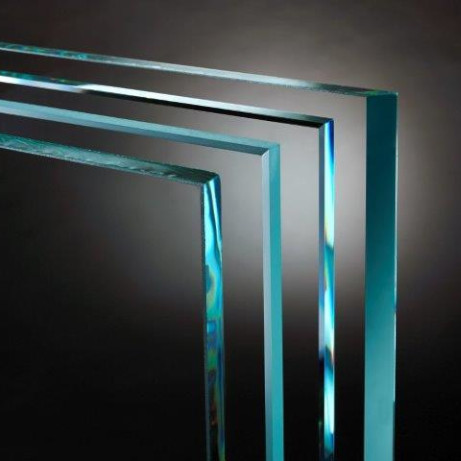

Specialty FabricationEdgework

Specialty Fabrication Edgework.

Edgework can improve safety, aesthetics of exposed edges, functionality, and cleanliness while improving dimensional tolerance, and heat-treating quality.

Edgework Options

All glass with edgework should be heat treated, either heat strengthened (HS) or fully tempered (FT). Edgework is completed prior to heat treating. For laminated glass, this results in a potential mismatch of up to 1/8″ between glass plies.

| Type | Description | Glass Thickness | Recommended Application | Appearance |

|---|---|---|---|---|

| Seamed | The simplest type of edgework, the sharp edges from 'as cut' glass are removed. | 1/8" to 3/4" | Concealed Edges | Seamed Finish As Cut |

| Flat Belt Ground and Seamed | The sharp edges and flares from 'as cut' glass are removed. | 1/8" to 3/4" | Structurally Glazed | Seamed Finish Belt Ground |

| Flat Ground with Arris | A flat machined edge with arrised edges and a satin finish. The arris width is 3/32" ± 1/32". | 1/8" to 3/4" | Exposed Edges or Butt Joint Edges with silicone seal | Ground Finish |

| Flat Polish with Arris | A flat machined edge with arrised edges and a polished finish. The arris width is 3/32" ± 1/32". | 1/8" to 3/4" | Exposed Edges | Polished Finish |

| Mitered* | A flat machined edge 1° to 45° from the cut edge. The thickness of glass remaining at the edge is 1/16" nominal with a tolerance of -1/64", +1/32". | 3/16" to 3/4" | Exposed Edges (polished) Butt Joint Edges with silicone seal (ground) | Polished or Ground Finish

|

*A customer sketch is required to identify the angle size and orientation. Viracon production drawings must be approved by the customer.

Viracon cannot guarantee the future availability of component parts manufactured or supplied by others that are incorporated into Viracon products. Contact your Viracon Representative for assistance.

Contact Us