Specialty FabricationNotches

Specialty Fabrication Notches.

Viracon can cut notches and cutouts for custom enhancements of monolithic glass using our Z. Bavelloni CNC Machine. Please refer to the following guidelines when requesting your specially fabricated glass products.

Notches and Cutouts Guidelines

All fabricated glass products with holes, notches and cutouts must incorporate tempering or heat-strengthening. Due to stresses created in the glass with these cutouts, annealed glass products are not appropriate.

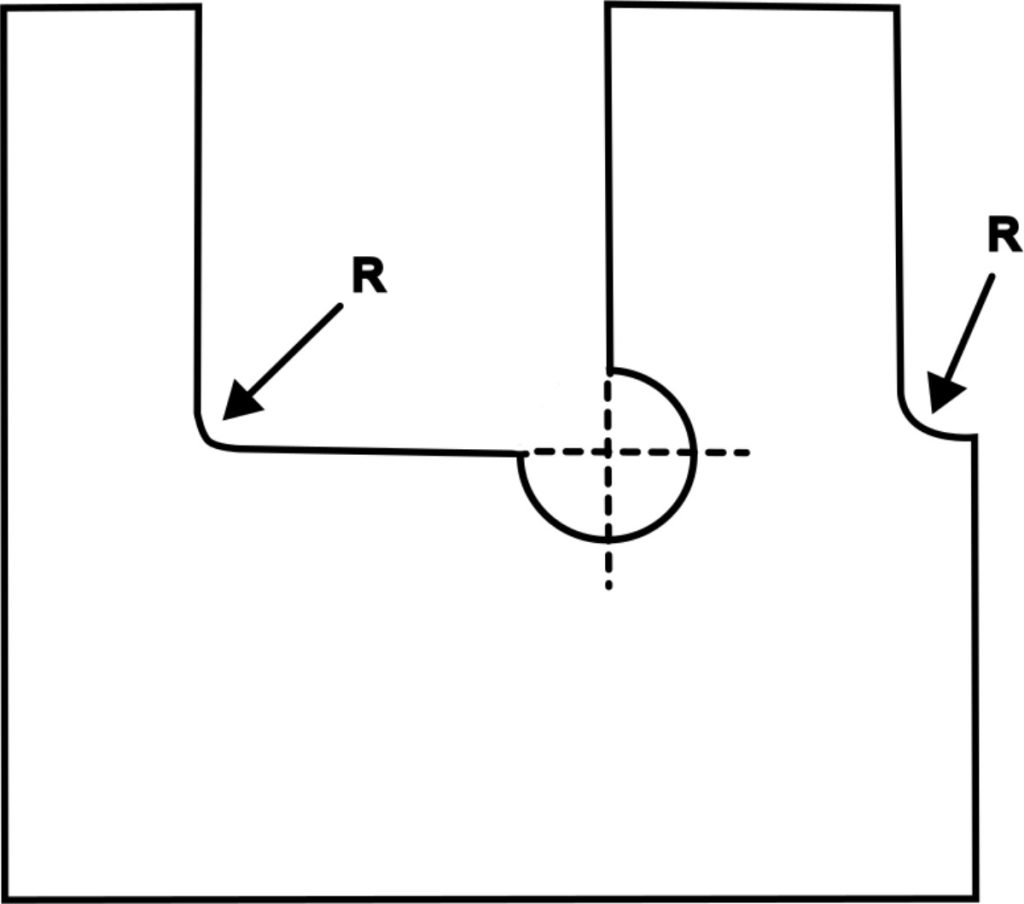

Fillets

To provide you with notches and cutouts, the corners must have fillets. A fillet is a rounded corner from which the straight edge emerges. The radius of the fillet must be equal to or greater than the thickness of the glass, but not less than 1/2″.

| Inches | |

|---|---|

| Glass Thickness | Minimum Radius |

| 1/8 | 1/2 |

| 5/32 | 1/2 |

| 3/16 | 1/2 |

| 1/4 | 1/2 |

| 5/16 | 1/2 |

| 3/8 | 1/2 |

| 1/2 | 1/2 |

| 5/8 | 5/8 |

| 3/4 | 3/4 |

| Millimeters | |

|---|---|

| Glass Thickness | Minimum Radius |

| 3 | 12 |

| 4 | 12 |

| 5 | 12 |

| 6 | 12 |

| 8 | 12 |

| 10 | 12 |

| 12 | 12 |

| 16 | 16 |

| 19 | 19 |

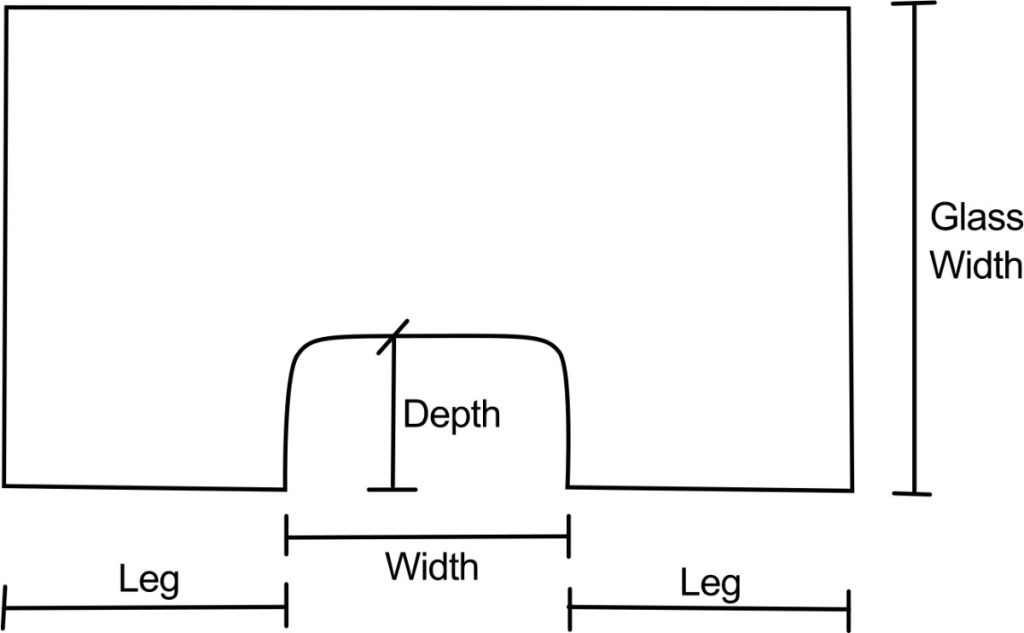

Fabrication Limitations:

- The depth or width of the notch or cutout can not have a dimension larger than 1/3 of the narrowest dimension of the lite.

- The leg length must be more than the depth of the notch.

- The leg length must be at least 3".

- The depth of the notch must be less than the width.

- The inside corner(s) must have a radius equal to, or greater than the thickness of the glass, but not less than 1/2".

Viracon cannot guarantee the future availability of component parts manufactured or supplied by others that are incorporated into Viracon products.